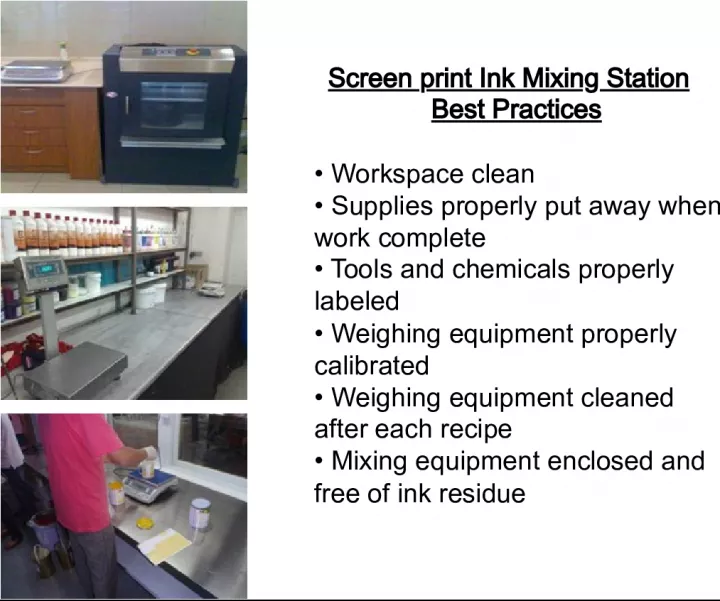

Best and Bad Practices of Screen Print Ink Mixing Station

Learn the best practices for maintaining a clean workspace, properly storing and labeling supplies and tools, and calibrating and cleaning weighing equipment. Avoid bad practices like working in a dirty environment, using contaminated supplies, or leaving mixing equipment open and filled with ink residue.

- Uploaded on | 2 Views

-

gregory

gregory

About Best and Bad Practices of Screen Print Ink Mixing Station

PowerPoint presentation about 'Best and Bad Practices of Screen Print Ink Mixing Station'. This presentation describes the topic on Learn the best practices for maintaining a clean workspace, properly storing and labeling supplies and tools, and calibrating and cleaning weighing equipment. Avoid bad practices like working in a dirty environment, using contaminated supplies, or leaving mixing equipment open and filled with ink residue.. The key topics included in this slideshow are . Download this presentation absolutely free.

Presentation Transcript

Slide1Screen print Ink Mixing StationBest Practices • Workspace clean • Supplies properly put away when work complete • Tools and chemicals properly labeled • Weighing equipment properly calibrated • Weighing equipment cleaned after each recipe • Mixing equipment enclosed and free of ink residue

Slide2Screen print Ink Mixing StationBad Practices • Workspace dirty • Supplies out and contaminated by improper use • Tools and chemicals not labeled or labeled improperly • Weighing equipment out of calibration • Weighing equipment contaminated by ink • Mixing equipment open and contaminated by ink residue

Slide3Screen print Ink Storage BestPractices • Storage room dedicated to ink • Room clean and free of clutter • Shelves available to organize ink by type and keep containers off the floor • Shelves clearly labeled • Ink chemicals containers properly labeled • Ink containers clean, any spills cleaned immediately • MSDS, spill clean up equipment available

Slide4Screen print Ink Storage Bad Practices • Storage combined within workspace • Dispensing or mixing allowed within storage area • More inventory than shelving allows, storage directly on the floor • Ink stored in open containers • Individual containers not labeled or improperly labeled • Containers and storage room contaminated with spilled ink • No MSDS or safety equipment available in case of spill

Slide5Screen Storage Best Practices• Screens properly cleaned, dried before put away for storage • Screens stored off the floor • Shelving labeled for easy retrieval

Slide6Screen Storage Bad Practices• Screens stacked against each other • Screens sitting on the floor • Ink residue left on screens

Slide7Squeegee/Mixing Tools StorageBest Practices • Squeegees / tools properly cleaned, dried before put away for storage • Cleanings chemicals properly labeled. PPE available. • Tools free of dried ink

Slide8Squeegee/Mixing Tool Storage BadPractices • Uncontrolled storage areas contaminated with ink • Squeeqees and other tools contaminated with ink • Squeegee type not properly labeled • Tools not properly labeled

Slide9Screen print Production Area Best Practices • No bulk ink storage in production area • Print stations clean • Spot cleaning performed in designated areas

Slide10Screen Print Production AreaBad Practices • Uncontrolled ink storage allowed at production stations • Trash and ink contaminate production areas • Uncontrolled/improperly labeled chemicals on production floor