Nanolatex-Based Nanocomposites: Control of Filler Structure and Reinforcement

This study explores the mechanical reinforcement of nanocomposites with a focus on controlling the filler structure and its interactions with the matrix. The microstructure of the filler network, percolation threshold, composite properties, and filler and matrix properties are analyzed.

- Uploaded on | 0 Views

-

janise

janise

About Nanolatex-Based Nanocomposites: Control of Filler Structure and Reinforcement

PowerPoint presentation about 'Nanolatex-Based Nanocomposites: Control of Filler Structure and Reinforcement'. This presentation describes the topic on This study explores the mechanical reinforcement of nanocomposites with a focus on controlling the filler structure and its interactions with the matrix. The microstructure of the filler network, percolation threshold, composite properties, and filler and matrix properties are analyzed.. The key topics included in this slideshow are Nanolatex, nanocomposites, mechanical properties, filler interactions, matrix interactions,. Download this presentation absolutely free.

Presentation Transcript

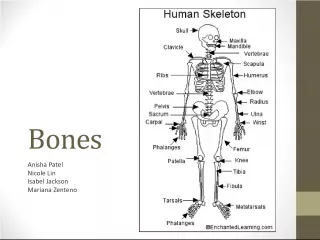

1. Nanolatex based nanocomposites: control of the filler structure and reinforcement . A. Banc 1 * , A-C. Genix 1 , C. Dupas, M. Chirat 1 , S.Caillol 2 , and J.Oberdisse 1 1 Laboratoire Charles Coulomb, Universit Montpellier 2, Montpellier, France 2 Institut Charles Gerhardt, Montpellier, France

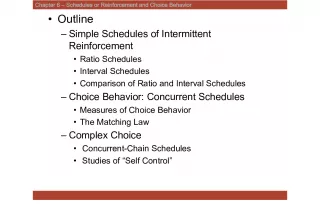

2. Mechanical reinforcement in nanocomposites ? M ICROSTRUCTURE Filler network Diluted regime Filler Percolation threshold Composite properties Filler properties + Matrix properties M ECHANICAL PROPERTIES Jouault et al. F ILLER - FILLER INTERACTIONS F ILLER - MATRIX INTERACTIONS

3. Model nanocomposites with tunable filler structure si30 nm Collodal silica + Drying Annealing Water evaporation Particles deformation Polymer diffusion Nanocomposite TUNABLE nanostructure: f( Si , Si / PEMA , M w ) PolyEthylMethacrylate (PEMA) Tg>Tamb Nanolatex PEMA 30 nm OR 200nm Mw 20, 50 or 160 kg/mol

4. E FFECT OF R latex / R si

5. Small Angle Scattering k i k s Wave vector q= - k s k i I(q)= f( , , P(q), S(q)) = Volume fraction = Scattering objects - matrix = Scattering lengh density P(q) = Form factor S(Q)= Structure factor q( -1 ) P(q) S(q) I(q) Silica nanoparticles P(q)

6. 0% 1% 3% 5% 10% Structure R silica ~R latex ~14 nm Q -2,4 Colloidal solutions R silica <

7. 5m 500nm 5m 5m 5m 500nm R silica ~R latex ~14 nm R silica <

8. Rheological properties G G G G G G G G Matrix 10% nanocomposite Silica structure little impacts G at low frequency (long times) N O IMPORTANT EFFECT OF THE SILICA STRUCTURE ON RHEOLOGICAL PROPERTIES ( Low strain: 0,2% ) x4

10. Structure: SAXS Mw= 160 000g/mol 50 000g/mol 20 000g/mol 10% 5% 3% 1% Matrix Well dispersed filler Fractal aggregates d f =2,4 d f =2,3 Bigger fractal aggregates R silica ~R latex ~14 nm

11. PEMA50 PEMA160 PEMA20 1% 3% 10% 500 nm Structure: TEM

12. Structure: Monte Carlo simulation Image analysis 1% nanocomposites: No inter-aggregate structure factor 160 000g/mol 20 000g/mol Monte Carlo simulation Kappa=12.5% Kappa>20% Correlation direct space and reciprocal space via simulation

13. Structure: 10% nanocomposites d* d* d* d*=2 /q* Model cubic network Silica networks whose the characteristic size decreases with Mw => decrease of the wall thickness 20 000g/mol 50 000g/mol 160 000g/mol

14. PEMA50 PEMA160 PEMA20 1% 3% 10% 500 nm Structure: overview d* d* d*

15. Rheological properties: matrices PEMA160 PEMA50 PEMA20 G G G G G G G N Master curve at annealing temperature (180C): Filler mobility: PEMA20 > PEMA50 > PEMA160

16. Rheological properties: nanocomposites Two filler volume fraction regimes: - < threshold viscoelastic material - > threshold elastic material Filler effect: -G at low frequency threshold <10%

17. At < threshold G~ 1/(3-df) G~ 1,7 Aggregate fractal dimension: df=2,4 (SAXS) Reaction Limited Aggregation -Slow aggregation In the weak-link regime : Shih et al, 1990 Rheology of fractal objets

18. d* d* d* At > threshold Fractal aggregates reinforce much more than the well dispersed filler . Power law ?

19. Conclusions - Prospects => Dynamical approaches of the mechanical reinforcement Model nanocomposites Various nanoparticle dispersions: well dispersed / fractal aggregates / porous network => Novel structures with mixtures of latex bead sizes Mechanical reinforcement Mostly at low frequency aggregated filler reinforce better than the well dispersed one Quantitative description of the filler structure : D IRECT SPACE R ECIPROCAL SPACE TEM SAXS Image analysis + Simulation => Behavior at large strains?