Offshore Wind Energy: Strategies and Experiences

This article explores the experiences of Bonus Energy A/S in offshore wind projects and their long term strategy for success. By prioritizing proven technology and gradually expanding into deeper waters, they have successfully developed 6 projects with a total of 128 turbines and 245 MW.

- Uploaded on | 0 Views

-

stephania

stephania

About Offshore Wind Energy: Strategies and Experiences

PowerPoint presentation about 'Offshore Wind Energy: Strategies and Experiences'. This presentation describes the topic on This article explores the experiences of Bonus Energy A/S in offshore wind projects and their long term strategy for success. By prioritizing proven technology and gradually expanding into deeper waters, they have successfully developed 6 projects with a total of 128 turbines and 245 MW.. The key topics included in this slideshow are Offshore Wind Energy, Bonus Energy A/S, Long Term Strategy, Demonstration Projects, Proven Technology,. Download this presentation absolutely free.

Presentation Transcript

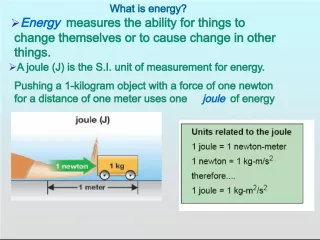

1. Offshore Wind 2004 Offshore Wind 2004 From Vindeby to Nysted A Manufacturers Experience Henrik Stiesdal Bonus Energy A/S

2. Bonus Offshore Wind Farms Bonus Offshore Wind Farms 6 Offshore Projects, 1991-2003 128 Turbines, total 245 MW

3. Long-Term Strategy Long-Term Strategy The long-term strategy behind offshore activities: Get one of the first, moderate-size demonstration projects to acquire longest possible experience Base offshore projects on proven turbine technology to avoid combination of new technology risks with offshore risks Accept early offshore projects only in shallow and/or less exposed waters and refuse projects in deep and/or exposed waters until complete offshore technology (turbine modifications, installation, service) proven

4. Vindeby Vindeby

5. Vindeby, Main Project Data Vindeby, Main Project Data Worlds first offshore wind farm: 11 x 450 kW, 1991 Built by ELKRAFT, owned by SEAS for demonstration of potential in offshore wind power Bonus scope of supply: Turbines, SCADA, installation, 2 years WOM Total project cost 7.0 M (1991) = 9.1 M (2003) Total project cost per MW installed 1.8 M (2003) Cost of Bonus supply 47% of total project cost

6. Vindeby, Turbine Details Vindeby, Turbine Details Offshore modifications implemented at Vindeby: Built-in nacelle crane for service works, can install larger crane for main component replacement Totally enclosed nacelle and tower Cooling with heat exchanges for gearbox and generator Climate control with dehumidifiers in nacelle and tower Transformer in bottom of tower

7. Vindeby, Infrastructure Details Vindeby, Infrastructure Details Essentially an onshore wind farm moved offshore: Water depths 2-5 m Moderate fetch (10-15 km) in prevailing wind direction Turbines in two rows, 8.5 D spacing in rows, 8.5 D spacing between rows Concrete caisson foundations, conical top to act as ice- breaker 10 kV wind farm grid voltage 10 kV land connection

8. Vindeby, Installation Vindeby, Installation Installation by onshore methods moved offshore: Foundations and electrical infrastructure installed separately by others Turbines installed with normal onshore mobile crane placed on standard offshore barge Turbines shipped two at a time, completely assembled with rotors 11 turbines installed in 12 days

9. Vindeby, Experiences Vindeby, Experiences 12 years of operation with no major problems: High turbine availability Climate control very efficient - turbines as new inside Higher incidence of lightning strikes than onshore Moveable crane for main components not used Conical foundations cause access problems due to standing waves Useful weather windows sometimes significantly shorter than predicted by statistics 10 kV voltage level for internal grid and land connection causes substantial grid losses (7%)

10. Vindeby, Landing Arrangements Vindeby, Landing Arrangements

11. Vindeby, Energy Production Vindeby, Energy Production

12. Middelgrunden Middelgrunden

13. Sams Sams

14. Nysted Nysted

15. Nysted, Main Project Data Nysted, Main Project Data Worlds largest offshore wind farm: 72 x 2.3 MW, 2003 Built by E2, owned jointly by E2, DONG and Sydkraft Bonus scope of supply: Turbines, SCADA, installation, 5 years WOM Total project cost app. 140 M (2003) Total project cost per MW installed app. 0.85 M (2003) Cost of Bonus supply app. 60% of total project cost

16. Nysted, Turbine Details Nysted, Turbine Details Updated offshore modifications based on Vindeby: Built-in nacelle crane for service works, can install two versions of larger cranes Totally enclosed nacelle and tower Cooling with heat exchanges for gearbox and generator, temperature control in narrow range Climate control with dehumidifiers in nacelle and tower Transformer in bottom of tower Automatic lubrication systems with 12+ months capacity Permanent on-line machine condition monitoring Dynamic power factor correction system and fault-ride- through capability

17. Nysted, Infrastructure Details Nysted, Infrastructure Details A true offshore wind power plant: Water depths 5-10 m Substantial fetch (80-100 km) in prevailing wind direction Turbines in grid pattern, 5.8 D spacing in rows, 10.3 D spacing between rows Ballasted concrete pedestal foundations, inverted cone at top to act as ice-breaker 33 kV wind farm grid voltage 132 kV land connection

18. Nysted, Installation Nysted, Installation A true offshore installation setup: Foundations and electrical infrastructure installed separately by others Turbines installed with A2SEA vessel Turbines shipped four at a time, loaded on vessel as towers in two sections, nacelles, and completely assembled rotors 72 turbines installed in 81 days

19. Nysted, Installation Nysted, Installation

20. Nysted, Experiences Nysted, Experiences Project still at early operational stage: Installation and commissioning according to schedule Taking-Over achieved one month ahead of schedule Minor teething troubles, mainly electrical and aerial warning lights Availability since Taking-Over 97%, not corrected for periods with no access 29 Nysted turbines each produced over 1 M kWh in December 2003, first and only time this level reached in Denmark

21. And then... And then... So much for past and present - What about the future?

22. A Historical Trend... A Historical Trend...

23. For a Reason For a Reason

24. Where Does This Lead Us? Where Does This Lead Us?

25. The Next Generation... The Next Generation... A next generation offshore is: Large (because large turbines make cheaper electricity than small turbines) But not too large (because organic growth provides more safety than big leaps) Fitted with further developments of the offshore modifications proven in previous projects, including Vindeby and Nysted Compliant with all grid requirements, providing fault ride-through and fully flexible regulation

26. Could Look Like This Could Look Like This

27. Bonus 3.6 MW Bonus 3.6 MW Main Data: 107 m rotor diameter 80-120 m hub height Rotor weight 80 t Nacelle weight excl. rotor 120 t 100 m tower weight 250 t Variable speed with full converter to provide maximum flexibility and grid compliance

28. Bonus 3.6 MW Bonus 3.6 MW Peculiar Data: At 10 m/s wind speed the amount of air passing through the rotor every second has a weight of 100 t The B52 blade root design bending moment in flatwise direction is 14.000 kNm The maximum tip deflection of the B52 blade is 7 m

29. Bonus 3.6 MW Bonus 3.6 MW Schedule: Prototype installed Summer 2004 0-series installed late 2004 / early 2005 First significant commercial projects second half 2005 Unlimited production early 2006

30. Relative Sizes Relative Sizes