Selection of Metallic Materials Beyond Steels: Focus on Aluminum Alloys

This lesson delves into the selection of metallic materials beyond steels, with a particular focus on aluminum alloys. We cover the properties, advantages, and disadvantages of aluminum alloys, including their relatively good corrosion resistance and electrical and heat conductivity, but limited strength and stiffness properties.

- Uploaded on | 0 Views

-

aspynrath

aspynrath

About Selection of Metallic Materials Beyond Steels: Focus on Aluminum Alloys

PowerPoint presentation about 'Selection of Metallic Materials Beyond Steels: Focus on Aluminum Alloys'. This presentation describes the topic on This lesson delves into the selection of metallic materials beyond steels, with a particular focus on aluminum alloys. We cover the properties, advantages, and disadvantages of aluminum alloys, including their relatively good corrosion resistance and electrical and heat conductivity, but limited strength and stiffness properties.. The key topics included in this slideshow are metallic materials, aluminum alloys, properties, advantages, disadvantages,. Download this presentation absolutely free.

Presentation Transcript

1. Lesson 4 2014

2. Selection of metallic materials (other metallic materials than steels)

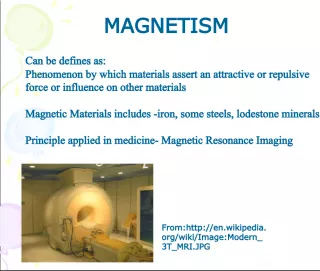

3. Other metallic materials than steels Aluminum alloys Magnesium alloys Zinc alloys Copper alloys Nickel alloys Titanium alloys STEELS - Caebon steels - QT-steels - Carburizing steels - Stainless steels - etc. Metallic materials REMEMBER TO WIDEN THE SELECTION AREA

4. Aluminum alloys Aluminum alloys in general Small density Relatively g ood corrosion resistance Limited strength and stiffness properties Good electrical conductivity Good heat conductivity Easy formability Disadvantage Moderate Advantage

5. Aluminum alloys in general Small density Aluminums density is about 1/3 of steels density BUT Aluminums modulus of elasticity is also about 1/3 of steels modulus of elasticity THEREFORE It is not so self-evident how much lighter the aluminum construction might be IN GENERAL The equal strength and stiffness properties are achieved with an aluminum structure which is only about 50 % lighter that the corresponding steel structure. Steel Aluminum Disadvantage Moderate Advantage

6. Aluminum alloys in general Relatively g ood corrosion resistance Disadvantage Moderate Advantage Depends on the affecting chemical environment - acidic alkaline - pH-value - mediums - Temperature - sea water - etc. Depends on the alloying of the selected aluminum: - Copper - Magnesium

7. Corrosion resistance of aluminum alloys In general the oxide layer protects the base material (5-10nm) The corrosion resistance can be improved by utilizing anodizing (electrolytic passivation process) Copper alloying decreases remarkably aluminums corrosion resistance In water and seawater aluminum alloys may suffer from localized corrosion Better corrosion resistance in seawater can be achieved by magnesium alloyed aluminums

8. The oxide layer is able to protect aluminums surface only between the pH-range of 48.5 Corrosion speed Acidic Neutral Alkaline

9. Aluminum alloys in general Very corrosive: - Lye - Sodium sulfide - Hydrochloric acid - Hydrofluoric acid - Sulfuric acid - Chlorine - Phosphoric acid Low or non-corrosive: - Boric acid - Arsenic acid - Carbonic acid - Formic acid ( if T < 50 C ) - Phenol ( if T < 120 C ) - Most of alcohols - Benzene, Toluene - Naphthalene - Styrene - Oxygen - Hydrogen - Nitrogen - Helium - Argon - Carbon monoxide - Carbon dioxide

10. Aluminum alloys in general Limited strength and stiffness properties Disadvantage Moderate Advantage Aluminums melting point is only 658C and low creeping strength might become a problem not higher than at > 100C. Aluminums fatigue strength is 0.350.55R M . Note that aluminums fatigue strength is usually expressed based on not more than 3-510 8 loading cycles. Note that aluminum products, which are made by casting suffer from even lower fatigue strength than products, which are made by forming. Under corrosive environmental loading aluminums fatigue strength decreases dramatically. At low temperatures aluminums strength values are higher than at room temperature and its ductility remains constant. Therefore aluminum alloys are used in cryogenics (e.g. vessels for liquid gases, under - 160C.

11. Aluminum alloys in general Good electrical conductivity Good heat conductivity Disadvantage Moderate Advantage Aluminums thermal conductivity is three times better compared with steels and cast irons. This property is utilized e.g. in electromechanical industry. Aluminum has good electrical conductivity and compared with copper, the weight of the wire made of aluminum, is only 50% of the weight of the wire made of copper. Alloying affects greatly both the electrical and thermal conductivity.

12. Aluminum alloys in general Easy formability Disadvantage Moderate Advantage Different types of standardized aluminum profiles are available. Due to aluminums easy formability customized profiles can easily be manufactured by extrusion. Profiles and plates can be coated for several purposes. Especially good formability can be achieved with magnesium and silicon alloyed aluminums.

13. 1000-series Pure aluminum Electrical conductivity (other alloys 8000-series) 3000-series Aluminum with manganese alloying 4000-series Aluminum with silicon alloying 5000-series Aluminum with magnesium alloying 6000-series Aluminum with magnesium and silicon alloying 7000-series Aluminum with zinc alloying 2000-series Aluminum with copper alloying High corrosion resistance in seawater No heat treatments available EN-AW-5754 Good suitability for anodizing Suitable for heat treatments EN-AW-6082 The mostly used grade in mechanical engineering EM-AW-6063 Aluminum profiles, tubes High strength but poor weldability Suitable for heat treatments EN-AW-7050 Airplanes EN-AW-7075 Airplanes Moderate weldability, corrosion resistance and good formability No heat treatments available EN-AW-3103 Car bodies Improved ductility and machinability Risk of corrosion Suitable for heat treatments EN-AW-2007 Excellent for turning Suitable for casting and powder metallurgy

14. Selection of the best aluminum alloy for the product PAY SPECIAL ATTENTION TO CLARIFY THE FOLLOWING REQUIREMENTS: 1. Corrosive environment 2. Temperature and acidic/alcaline ranges 3. Possible dynamic loading 4. Intended manufacturing methods in production REQUIREMENTS PROFILE COMPARISON OF MATERIAL PROPERTIES COMPARE CAREFULLY AVAILABLE DIFFERENT OPTIONS: 1) 10008000 series (optimum alloying) 2) Heat treatments (if possible) 3) Anodizing 4) Standardized profiles and other bulk materials SFS-EN 515 Aluminum and aluminum alloys. Temper designations. SFS-EN 573-15 Aluminum and aluminum alloys. Chemical composition, numerical designation system, forms of products and codification of standardized products.

16. Remember, that it is important to recycle aluminum! The manufacturing process ,which utilizes recycled aluminum needs only 5% of that energy amount required in the process starting from ore (bauxite). About 75% of aluminum is recycled nowadays.

17. Copper and copper alloys Brasses Bronzes Nickel Silver Tough pitch copper Deoxidized copper Oxygen- free copper Pure copper and copper alloys Pure copper Copper alloys

18. Grades of pure copper High electrical conductivity Cu-OF (oxygen-free copper) Copper amount at least 99,95 % Extremely hight electrical conductivity Cu-OFE (oxygen-free copper, electronic grade Copper amount at least 99,99 %. The most common copper grade : Cu-ETP (tough pitch copper) Coppers for general use are usually deoxidized grades : Cu-DHP (phosphorus-deoxidized copper high residual phosphorus) Cu-DLP (phosphorus-deoxidized copper low residual phosphorus

19. Copper alloys Copper alloys contain at last 2.5% alloying components: BRASSES BRONZES NICKEL SILVER Zinc alloys (different grades of brasses) Tin, lead, nickel and zinc (different grades of tin-bronzes) Aluminum (different grades of aluminum-bronzes) Beryllium (different grades of beryllium-bronzes) Silicon (different grades of silicon-bronzes) Nickel and zinc (different grades of nickel silver) Nickel-Copper alloys

20. Pure copper and copper alloys in general Some special properties available Moderate strength properties Poor weldability Relatively good corrosion resistance Good electrical and thermal conductivity Easy formability, machinability and castability Disadvantage Moderate Advantage

21. Pure copper Good electrical and thermal conductivity Disadvantage Moderate Advantage High electrical conductivity: Cu-OF (oxygen-free copper) Extremely high electrical conductivity: Cu-OFE (oxygen-free copper, electronic grade)

22. Pure copper and copper alloys in general Easy formability, machinability and castability Disadvantage Moderate Advantage Unlike usually known che machinability properties of copper alloys, especially many brasses, are excellent. Maybe this is because pure copper is difficult for machining. Copper alloys have excellent formability properties both for cold and hot forming. By using suitable alloying copper alloys have good castability properties

23. Pure copper and copper alloys in general Some special properties available Disadvantage Moderate Advantage Copper-Beryllium alloys have excellent wear resistance. However, they have poor machinability and weldability properties. Copper alloys have good resistance against the growth of microbes. Copper alloys are non- magnetic metallic materials.

24. Pure copper and copper alloys in general Relatively good corrosion resistance Disadvantage Moderate Advantage Good corrosion resistance in freshwater seawater, steam soil climatic conditions corrosion rate 0-2,2 m/year In sulphuric conditions corrosion resistance is poor Typical corrosion types are: Erosion - Flow rates in tubes and pipelines should be limited Selective corrosion - Dezincification of brasses Stress corrosion - Especially brasses suffer from stress corrosion - Nitrides and ammonia increase the risk Because copper is a relatively noble metal, it can cause the reaction of galvanic corrosion with the adjacent materials

25. Pure copper and copper alloys in general Moderate strength properties Disadvantage Moderate Advantage Modulus of elasticity, 0.2- limit, ultimate tensile strength and elongation to fracture increase when the temperature decreases. Ductility increases when the temperature decreases. Ultimate tensile strength and 0.2-limit decrease when temperature increases. Creeping strength becomes critical already at 100-200C depending in the alloying. Fatigue strength difficult to establish, endurance limit describes the stress to cause the fracture at certain number of loading cycles (100106). Typically the endurance limit is only about 1/3 of R M Strength is highly depending on the alloying, temper designation and manufacturing process .

26. Pure copper and copper alloys in general Poor weldability Disadvantage Moderate Advantage Poor weldability porosity of seams decreased strength Decreased ductility Strict requirements of cleanness

27. Standardization SFS-ISO 1190-1. Copper and copper alloys Chemical composition and designation. SFS-EN 1173. Copper and copper alloys. Temper designations. SFS-EN 1412. Copper and copper alloys. Numerical designation system. Examples: Cu-OF-04 CuZn39Pb2 GZ-CuPb10Sn

28. Some application areas of copper: Constructions where climatic loading is affecting Water piping lines Seawater applications Heat exchangers Steam power plant applications Electrical industry

30. Nuclear fuel waste management

31. Property Result of comparison Yeld strength The yeld strength of steels is 2.510 times higher. Fatigue strength The fatigue strength of steels is 26 times higher. Hardness The maximum hardness of steels is about 2 times higher. The hardness of some CuBe-alloys might be equal or higher Elongation to fracture Copper alloys have (in average) 1.5 times higher elongation. Modulus of elasticity The modulus of elasticity of steels is 1.53 times higher. Comparison of steels and copper alloys

32. One example of selecting the optimal copper grade: The power feeding strip of a smart antenna application should meet the following requirements: High priority (demands): Excellent electrical performance to avoid power losses Good environmental corrosion resistance in different types of climate conditions Lower priority (wishes) Acceptable weldability with the radiating elements and feeding pins Ability to function as springs to ensure good electrical contact and easy assembly

33. RADOME RADIATING ELEMENTS POWER FEEDING PINS GROUND PLANE POWER FEEDING STRIPS BODY MADE OF FOUR-CORNERED BARS REAR PLATE N-TYPE CONNECTORS HOUSING OF ELECTRONICS JOINING COMPONENTS OF THE SMART ANTENNA

34. Deoxicidized Cu-DHP Moderate electrical conductivity Acceptable weldability Performance about 70% of the maximum Copper-Tin alloy CuSn6 Moderate electrical conductivity Good corrosion resistance Moderate weldability Property to function as a spring is possible Performance only about 10% of the maximum Oxygen free Cu-OF Best electrical conductivity Maximum performance

35. Selection of the best copper alloy for the product REQUIREMENTS PROFILE COMPARISON OF MATERIAL PROPERTIES Electrical conductivity Thermal Conductivity Corrosion Resistance Easy Formability Easy Machinability Easy Castability Corrosion resistance PURE COPPERS Oxygen free coppers PURE COPPERS deoxidized coppers BRASSES BRONZES OTHER COPPER ALLOYS Wires Piping Components Machine parts SFS-ISO 1190-1. Copper and copper alloys Chemical composition and designation. SFS-EN 1173. Copper and copper alloys. Temper designations. SFS-EN 1412. Copper and copper alloys. Numerical designation system.

36. Titanium alloys Different grades of titanium alloys ASTM Grades 2 and 3 ASTM Grade 1 ASTM Grade 4 ASTM Grade 5 ASTM Grades 7 and 8 Other grades

37. Most important alloys:

38. Some typical application areas: Gr 1: Good formability e.g. for stretch forming or deep drawing. Gr 2 ja 3: Grades for many applications in chemical process industrial and mechanical engineering Gr 4: High hardness, which suitable for springs and components loaded by wear Gr 7 ja 8: For applications where improved corrosion resistance is required. Gr 5: For applications where both high static and fatigue strength are required.

39. Titanium alloys in general Density (in average) 4540 kg/m3 Modulus of elasticity (in average) 108 000 N/mm2 Melting temperature (in average)1670 o C Properties can be tuned by alloying Aluminum Lead Nickel Molybdenum Vanadium

40. The strength of titanium alloys exceeds the values of steels, but the weight is 45% lighter! The weight of titanium alloys is 60% higher than the weight of aluminum alloys, but the strength is two time higher! The maximum strength of the best titanium alloys is competitive with the best stainless and QT-steels! The ultimate tensile strength can be increased up to 1700 n. 1800 MPa.

41. Titanium alloys Titanium alloys in general Good corrosion resistance Good strength / weight-ratio Special application areas Moderate manufacturability Limited strength properties in elevated temperatures Excellent properties in cold environments Disadvantage Moderate Advantage

42. Titanium alloys in general Good strength / weight-ratio Disadvantage Moderate Advantage Titanium alloys are used in applications, where high strength/weight-ratio is required together with good corrosion resistance. Titanium turbine blades

44. By appropriate alloying the strength values can be increased but at the same time the values of modulus of elasticity will decrease!

45. Titanium alloys in general Excellent properties in cold environments Disadvantage Moderate Advantage Because brittle fractures are not very likely with titanium alloys, they are applied for cryogenic applications (temperatures below -80C). The yeld strength of titanium alloys increases while the temperature decreases. The impact strength of pure titanium and slightly alloyed titanium alloys increases while the temperature decreases. Titanium has excellent corrosion resistance in cold environments.

46. Titanium alloys in general Limited strength properties in elevated temperatures Disadvantage Moderate Advantage ?

47. + 300C -50% ! + 500 C -50% ! + 300C -20% !

48. Titanium alloys in general Good corrosion resistance Disadvantage Moderate Advantage Titanium and titanium alloys are used in chemical process equipment and in wood processing industry if the corrosion resistance of stainless steels is not high enough . Corrosive environment does not decrease the fatigue strength of titanium.

49. Properly selected titanium alloys can withstand: Seawater (corrosion rate not more than ~ 8 m/v) Wet chlorine (if humidity >0,005% H2O) Nitric acid under its boiling temperature Oxidising salines under their boiling temperatures CuCl2, FeCl3, CuSO4, K2Cr2O Hypoclorites Diluted Hydrochloric acid and Sulfuric acid Titanium alloys do not withstand: Hot alkaline salines Dry Chloride Nitric acid above its boiling temperature Molten salines (e.g NaCl, LiCl, Fluorides, CaCl2 ) Hydrogen fluoride in water solutions (HF, fluoride acid) Fluorine Oxalic acid, Formic acid Elevated temperature decreases the corrosion resistance even in normal air atmosphere

50. Titanium alloys in general Good corrosion resistance Disadvantage Moderate Advantage Remember to check! pH- range Joint effects Temperature Humidity Chemicals Concentration !

51. Titanium alloys in general Moderate manufacturability Disadvantage Moderate Advantage Note: Insufficient surface roughness after machining or even a tiny crack on the surface of the titanium component decreases the fatigue strength remarkably! Usually semi-products can be used: - Sheet metal - Tubes - Bars - Profiles - Wires - Screws In general, titaniums weldability is good, because its thermal expansion is low and deformations due to heat input remain small. Usually TIG- or plasma processes are applied. Weldability with other metals is poor, because of brittle compounds with other materials, which are formed during welding. Welded constructions might suffer easily from porosity and decreased ductility due to titaniums reactions with Oxygen and Nitrogen during welding .

52. Titanium alloys in general Moderate manufacturability Disadvantage Moderate Advantage Machinability is challenging due to: - addhesive reactions with the cutting tool - tendency to suffer from work-hardening - low modulus of elasticity - low thermal conductivity Note: Insufficient surface roughness after machining or even a tiny crack on the surface of the titanium component decreases the fatigue strength remarkably! Cold forming is easy for pure titanium and slightly allowed titanium alloys. Titanium alloys tend to work-harden during the forming processes.

53. Titanium alloys in general Special application areas Disadvantage Moderate Advantage One famous adaptive memory material is based on Titanium- Nickel-alloying Titanium nitrides and carbides are used as coatings in cutting edges and other tools. Utilization in cryogenic applications!

54. Selection of the best titanium alloy for the product REQUIREMENTS PROFILE COMPARISON OF MATERIAL PROPERTIES Light weight together with high strength Good formability Corrosion resistance with high strength and light weight High strength and light weight Use in cold environment Grade 1 Grades 28 Grade 5 (+ others) Semi-products Process industry Airplanes etc. GRADES 18 Detailed alloys and their chemical composition

55. Magnesium alloys Magnesium alloys in general Limited corrosion resistance Light weight material Special application areas Standardized alloys Limited strength properties Surprisingly good manufacturability Disadvantage Moderate Advantage

56. Magnesium alloys in general Light weight material Disadvantage Moderate Advantage Density 1740 kg/m 3 . Modulus of elasticity 45 000 N/mm 2 Magnesium is the most light weight material for constructions. Magnesium is used in applications where either the mass or inertia should be minimized (airplanes, camera bodies, vehicles etc.).

57. Magnesium alloys in general Surprisingly good manufacturability Disadvantage Moderate Advantage Magnesium alloys are available both for casting and forming. If impurities are removed properly from the surfaces, magnesium alloys can be welded with TIG-, MIG- or ERW- processes . Magnesium alloys can be machined easily with e.g. tools made of HS-steels by using high cutting speeds and large feeds. There is always the risk of fire when magnesium is welded, machined or heat treated. Do not try to put out the fire with water!

58. Magnesium alloys in general Special application areas Disadvantage Moderate Advantage

59. Magnesium alloys in general Disadvantage Moderate Advantage Standardized alloys Identification codes of magnesium alloys are based on ASTM standards. Typical alloying components: Al (7-10 %) Zn (0.5-2.4 %) Mn ( 0.1 %) E.g. AZ81A

60. Magnesium alloys in general Limited strength properties Disadvantage Moderate Advantage With best magnesium alloys the yeld strength can exceed 300 MPa and tensile strength 400 MPa.

61. Magnesium alloys in general Limited corrosion resistance Disadvantage Moderate Advantage Sufficient corrosion resistance for the purposes of aircraft and process industries. Corrosion resistance can be improved by adding the content of aluminium: Stress corrosion is almost totally avoided if the content of aluminium is Al%>1.5. No risk of intergranular corrosion. Fe, Ni, Co and Cu decrease the corrosion resistance at elevated temperatures. High risk of galvanic corrosion with Fe, Ni, Cu ja Ti . Chloride in water solution increases the corrosion speed.

62. Nickel-Based Superalloys Nickel-Based Superalloys MONEL NIMONIC INVAR INCONEL INCOLOY HASTELLOY ELINVAR

63. Nickel-Based Superalloys MONEL Ni 60-70%, rest Cu Excellent corrosion resistance especially in seawater. If Al and Ti are added, higher strength will be achieved.

64. Nickel-Based Superalloys HASTELLOY Corrosion resistance is excellent even against hydrochloric acid and sulfuric acid. These type of alloys are able to withstand fire ! Hastelloy B (65 % Ni, 30 % Mo, 5 % Fe) Hastelloy C (64 % Ni, 16 % Cr, 16 % Mo )

65. Nickel-Based Superalloys INCONEL INCOLOY Corrosion resistance against various acids is excellent. Are able to withstand fire ! Also creeping strength guaranteed up to 815C. - Inconel X (75 % Ni, 14 % Cr, 6 % Fe, 0.7 % Al, 2.5 % Ti, 1 % Nb, 0.05 % C) - Nimonic 80A (73 % Ni, 20 % Cr, 2,3 % Ti, 1,2 % Al NIMONIC

66. Nickel-Based Superalloys INVAR Fe-Ni-alloy (36% Ni) No remarkable heat expansion .

67. Nickel-Based Superalloys ELINVAR Fe-Ni-Cr-alloy (34-37% Ni and 15% Cr). Modulus of elasticity is non- dependent of the temperature.

68. Gas turbine construction

69. Zinc alloys Typically used in mass production of pressure casting Low melting points, easy to cast thin wall thicknesses Typical aluminum content is about 4% By increasing the amount of aluminum (up to 827%), the strength can be improved

70. Scandium (Sc) Yttrium (Y) Lanthanum (La) Cerium (Ce) Praseodymium (Pr) Neodymium(Nd) Promethium (Pm) Samarium (Sm) Europium (Eu) Gadolinium (Gd) Terbium (Tb) Dysprosium (Dy) Holmium (Ho) Erbium (Er) Tulium (Tm) Ytterbium (Yb) Lutetium (Lu) RARE-EARTH METALS

71. Catalytic converters Catalytic converters Metal-hybrid batteries Metal-hybrid batteries Permanet magnets Permanet magnets Metallurgy and material science Metallurgy and material science Polishing technology Polishing technology Optics Optics Fluorescent materials Fluorescent materials Oil refineries Oil refineries Ce, La, Nd Ce, La, Nd La, Ce, Pr, Nd La, Ce, Pr, Nd Nd, Pr, Dy, Tb, Gd, Sm Nd, Pr, Dy, Tb, Gd, Sm Ce, La, Nd, Er, Gd, Yb Ce, La, Nd, Er, Gd, Yb Eu, Y, Tb, La, Dy, Ce, Pr, Gd Eu, Y, Tb, La, Dy, Ce, Pr, Gd Ce, Tb, Dy, Y Ce, Tb, Dy, Y Ce, La, Pr Ce, La, Pr La, Ce, Pr, Nd La, Ce, Pr, Nd Vehicles, cars Vehicles, cars Electric and hybrid cars Electric and hybrid cars Electric and hybrid cars, wind energy Electric and hybrid cars, wind energy Cameras, lenses Cameras, lenses Fluorescent lams, LCD- displays and -monitors Fluorescent lams, LCD- displays and -monitors Steels, castirons, ceramics Steels, castirons, ceramics Computer and mobile phone displays and monitors Computer and mobile phone displays and monitors Petrol (Gasoline) Petrol (Gasoline) Application area Materials Products RARE-EARTH METALS

75. During the past few years the production of rare-earth metals has exceeded more than 130 000 tons. About 90% was produced in China. The largest amounts of rare-earth metals production consist of Cerium ja Lanthanum (about 70 %) Next come such materials as Neodymium, Yttrium, Praseodymium and Samarium.

76. From the view point of sustainability or green values in engineering it is sad that only 1% on rare-earth metals are recycled at the moment. Due to the tiny amount on rare-earth metals in separate products it is not yet cost-effective to try to collect and recycle these materials. One trend is to try to replace the rare-earth metals with some other materials or technologies to improve sustainability.

77. ECO-EFFICIENCY OF THE MATERIAL Minimize the amount of material(s) If possible utilize waste material for energy production Repair the product for its initial use and purpose Utilize material for producing new products

78. Case example 1. Material group Key aspects of comparing corrosion resistance: Titanium alloys Reasonable corrosion resistance in different types of environments together with reasonable strength. Expensive. Stainless steels Tend to suffer from localized, crevice and stress corrosion and also corrosion fatigue. In general lower corrosion resistance compared with Titanium. Reinforced plastic Limited corrosion resistance together with limited highest operating temperature. Difficult to join. Fluoropolymers Better resistance in acidic and alkaline environments compared to Titanium. Low strength. Difficult to join. Copper alloys Reasonable price but only moderate corrosion resistance compared with Titanium Nickel alloys Compared with Titanium maximum operating temperature is higher but structures become heaver and corrosion resistance is lower Zircon Withstands better in reductive environments than Titanium. Expensive. Tantalum Withstands better both in reductive and oxidation environments than Titanium. Expensive.

79. Case example 2. Requirements of a slide bearing Aluminium bronze Fluoro- polymer PTFE Property ratio Al : PTFE Maximum load bearing capacity 35 MPa 136 MPa 1 : 4 Maximum operating temperature 260C 260C 1 : 1 Wear resistance (adhesive wear in range 15) 4 2 2 : 1 Own mass (based on density) 7.6 2.6 3 : 1 Price (Relative) 90 200 1 : 2